Poster ID:1140779553

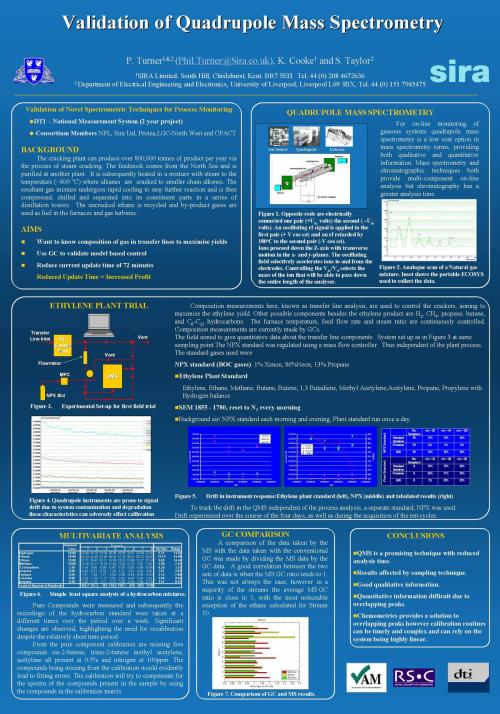

Validation of Quadrupole Mass Spectrometry

Author:Dr. Phillip Turner

Abstract/Description:

The cracking plant can produce over 800,000 tonnes of product per year via the process of steam cracking. The feedstock comes from the North Sea and is purified at another plant. It is subsequently heated in a mixture with steam to the temperature (~800 °C) where alkanes are cracked to smaller chain alkenes.

The resultant gas mixture undergoes rapid cooling to stop further reaction and is then compressed, chilled and separated into its constituent parts in a series of distillation towers. The uncracked ethane is recycled and by-product gases are used as fuel in the furnaces and gas turbines.

Poster presented at:

Chemistry in the Oil Industry VII

This author has 2 other posters, click to view

© ConferencePostersOnline 2006